PFC BRAKES Revolutionizing Rotor Designs with ABS Tone Ring

Clover, SC - Nearly two decades ago, PFC Brakes redefined rotor construction with a groundbreaking innovation that addressed a critical flaw in traditional tone ring rotor designs.

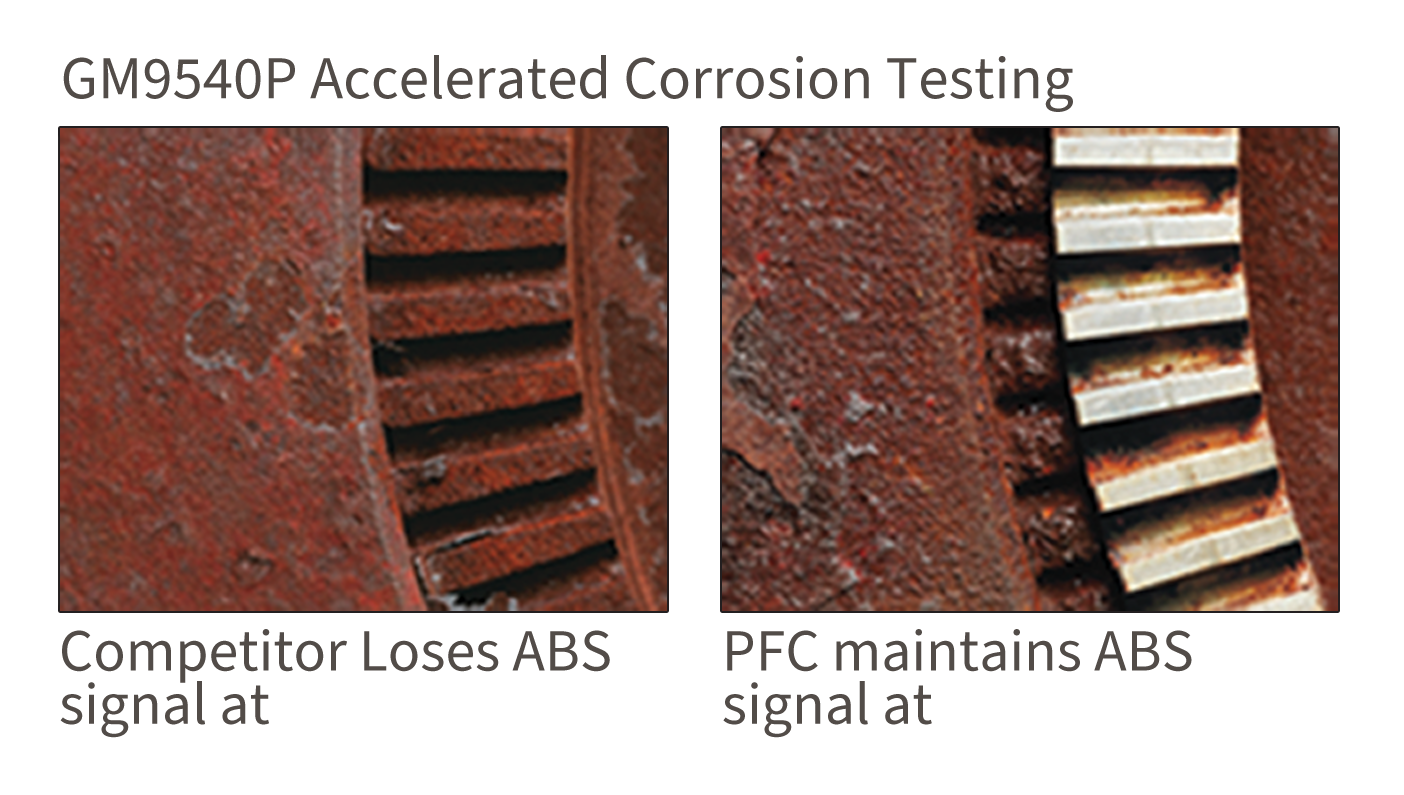

The widely used “cast-in” one-piece rotor tone ring was proving increasingly unreliable, particularly in regions where snow and salt melt technologies were advancing rapidly. Corrosive environments were causing ABS signal loss, forcing premature rotor replacements—even when the friction surfaces remained well within usable limits.

The industry needed a solution. PFC Brakes delivered.

THE ZERO FAILURE ISOLATED ABS TONE RING:

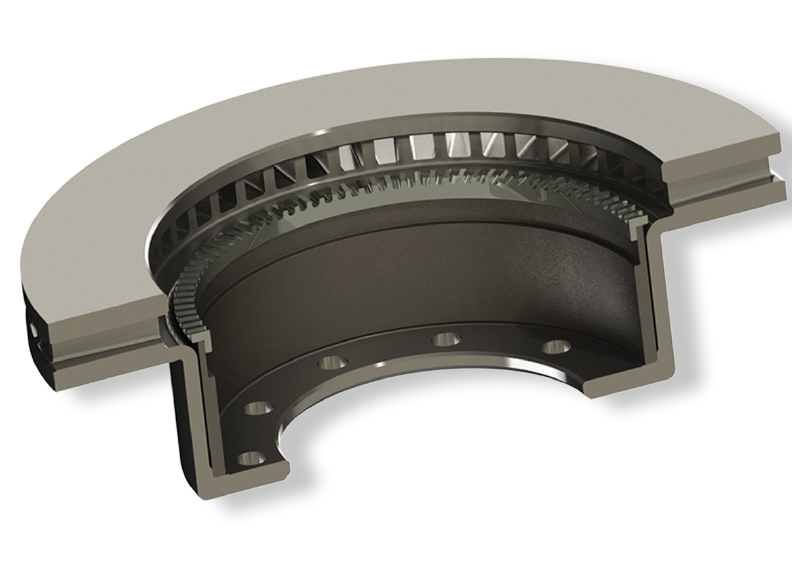

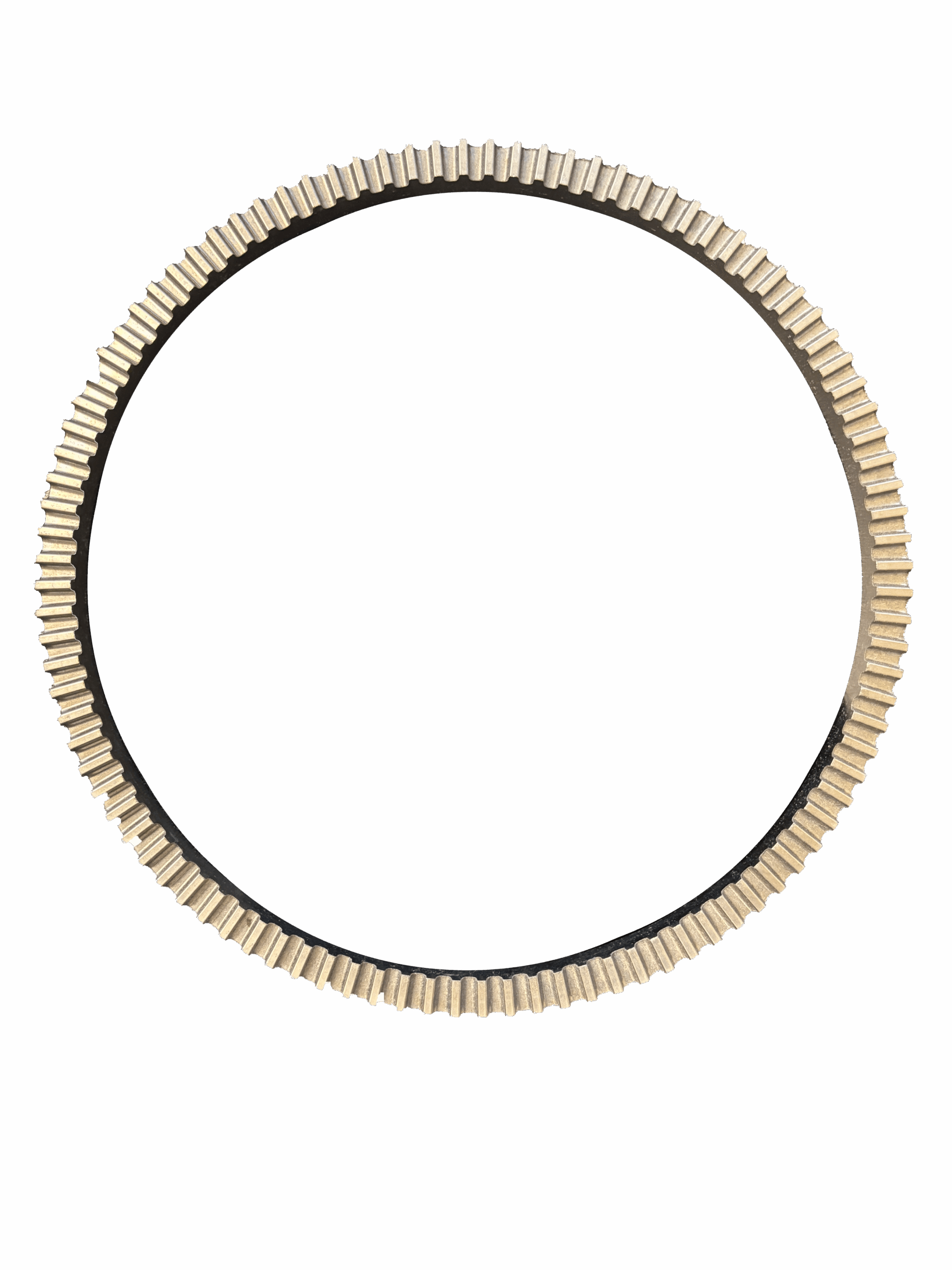

In response to this widespread issue, PFC introduced its patented zinc-nickel plated Zero Failure Isolated ABS Tone Ring, solving the corrosion-induced failures plaguing the transportation sector.

By separating the tone ring from the rotor casting and applying a corrosion-resistant plating, PFC created a product that could withstand even the harshest and aggressive North American climates.

Independent GM9540P corrosion tests—featuring high-temperature heat soaks—proved the durability of the design, where PFC rotors lasted over five times longer than traditional one-piece designs.

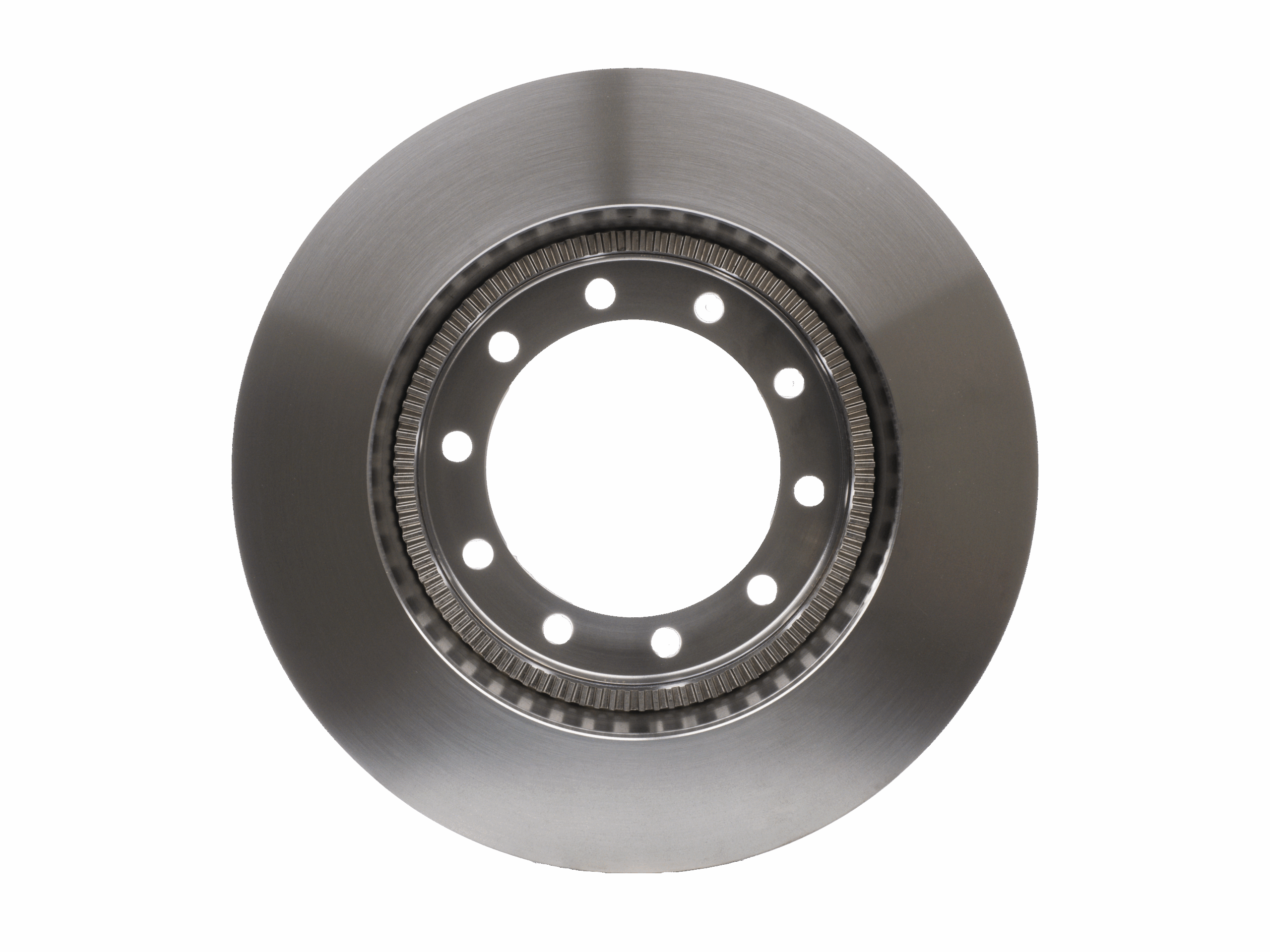

BUILT FOR MEDIUM-DUTY VEHICLES:

These models are specifically designed for demanding Medium Duty vehicles, including widely used platforms such as School Buses and Box Trucks. With extended rotor lifespan and improved ABS signal reliability, fleets benefit from reduced downtime, lower maintenance frequency, and substantial cost-per-mile savings—not to mention enhanced safety.

PFC Brakes remains committed to delivering cutting-edge solutions that meet real-world challenges. Our isolated ABS tone ring rotors continue to outperform and outlast traditional designs in the toughest environments.